What are the common production processes for parallel plate capacitors?

Common Production Processes for Parallel Plate Capacitors

I. Introduction

Parallel plate capacitors are fundamental components in electronic circuits, serving as essential elements for energy storage, filtering, and timing applications. These capacitors consist of two conductive plates separated by a dielectric material, which allows them to store electrical energy in an electric field. The importance of capacitors in modern electronics cannot be overstated, as they play a critical role in everything from power supply circuits to signal processing. This blog post will explore the common production processes for parallel plate capacitors, detailing the materials used, design considerations, and the various stages of manufacturing.

II. Materials Used in Parallel Plate Capacitors

A. Conductive Materials

The conductive plates of parallel plate capacitors are typically made from metals or conductive polymers.

1. **Metals**: Aluminum and copper are the most commonly used metals due to their excellent electrical conductivity and availability. Aluminum is often favored for its lightweight and cost-effectiveness, while copper is chosen for its superior conductivity.

2. **Conductive Polymers**: These materials are increasingly being used in applications where flexibility and lightweight properties are essential. Conductive polymers can be tailored to specific applications, providing a balance between conductivity and mechanical properties.

B. Dielectric Materials

The dielectric material is crucial for the capacitor's performance, as it determines the capacitor's ability to store charge.

1. **Types of Dielectrics**: Common dielectric materials include ceramics, plastics, and mica. Ceramic dielectrics are popular for their high dielectric constant and stability, while plastics offer flexibility and ease of processing. Mica is known for its excellent thermal stability and low loss characteristics.

2. **Properties of Dielectric Materials**: The dielectric constant, breakdown voltage, and temperature stability are key properties that influence the performance of the capacitor. Selecting the right dielectric material is essential for achieving the desired capacitance and reliability.

III. Design Considerations

A. Geometric Configuration

The design of parallel plate capacitors involves careful consideration of geometric parameters.

1. **Plate Area**: The surface area of the plates directly affects the capacitance. Larger plate areas allow for more charge storage, increasing the capacitance.

2. **Plate Separation**: The distance between the plates is inversely related to capacitance. Closer plates result in higher capacitance, but this must be balanced against the risk of dielectric breakdown.

B. Capacitance Calculation

1. **Formula for Capacitance**: The capacitance (C) of a parallel plate capacitor can be calculated using the formula:

\[

C = \frac{\varepsilon A}{d}

\]

where \( \varepsilon \) is the permittivity of the dielectric material, \( A \) is the area of one plate, and \( d \) is the separation between the plates.

2. **Impact of Design on Performance**: Variations in plate area and separation can significantly impact the capacitor's performance, making it essential to optimize these parameters during the design phase.

IV. Common Production Processes

A. Substrate Preparation

The production of parallel plate capacitors begins with substrate preparation.

1. **Cleaning and Surface Treatment**: The substrate must be thoroughly cleaned to remove any contaminants that could affect adhesion and performance. Surface treatments, such as plasma cleaning or chemical etching, may be employed to enhance surface properties.

2. **Substrate Material Selection**: The choice of substrate material is critical, as it must support the conductive and dielectric layers while maintaining structural integrity.

B. Electrode Fabrication

The next step involves fabricating the conductive electrodes.

1. **Thin Film Deposition Techniques**:

a. **Physical Vapor Deposition (PVD)**: This technique involves vaporizing a solid material in a vacuum and allowing it to condense on the substrate, forming a thin film. PVD is known for producing high-quality films with excellent uniformity.

b. **Chemical Vapor Deposition (CVD)**: CVD involves chemical reactions that deposit material onto the substrate. This method is particularly useful for creating complex geometries and high-purity films.

2. **Screen Printing and Stamping**: For larger-scale production, screen printing and stamping techniques can be employed to apply conductive inks or pastes onto the substrate, allowing for rapid and cost-effective electrode fabrication.

C. Dielectric Layer Application

Once the electrodes are in place, the dielectric layer is applied.

1. **Deposition Methods**:

a. **Spin Coating**: This technique involves depositing a liquid dielectric material onto the substrate and spinning it to achieve a uniform layer. Spin coating is widely used for its simplicity and ability to produce thin films.

b. **Layer-by-Layer Assembly**: This method involves alternating layers of dielectric and conductive materials, allowing for precise control over thickness and properties.

2. **Curing and Drying Processes**: After application, the dielectric layer must be cured or dried to achieve the desired properties. This may involve heat treatment or exposure to UV light, depending on the materials used.

D. Assembly of Capacitor Structure

The assembly process involves stacking and aligning the layers.

1. **Layer Stacking**: The dielectric layer is sandwiched between the conductive plates, and care must be taken to ensure proper alignment to avoid short circuits.

2. **Alignment and Bonding Techniques**: Various bonding techniques, such as adhesive bonding or thermal compression, are used to secure the layers together, ensuring mechanical stability and electrical performance.

E. Encapsulation and Packaging

The final steps involve encapsulating and packaging the capacitors.

1. **Protective Coatings**: To enhance durability and protect against environmental factors, capacitors are often coated with protective materials. This can include conformal coatings or potting compounds.

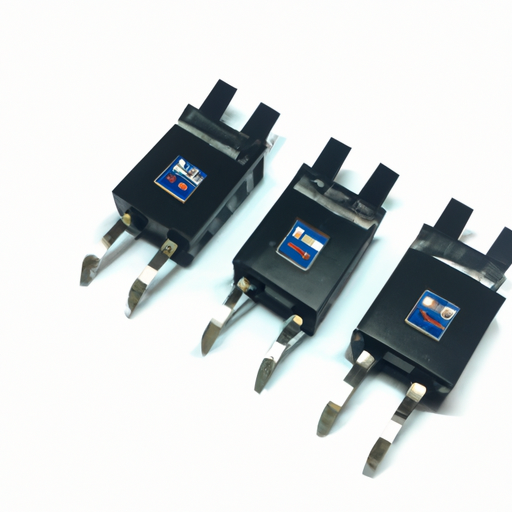

2. **Packaging Materials and Techniques**: The choice of packaging is crucial for ensuring the reliability and longevity of the capacitors. Common packaging methods include surface mount technology (SMT) and through-hole technology, depending on the application.

V. Quality Control and Testing

Quality control is essential throughout the production process to ensure that capacitors meet performance standards.

A. Electrical Testing

1. **Capacitance Measurement**: Capacitors are tested for their capacitance values to ensure they meet design specifications. This is typically done using LCR meters.

2. **Leakage Current Testing**: Leakage current tests are performed to assess the integrity of the dielectric material and ensure that the capacitor does not allow unintended current flow.

B. Mechanical Testing

1. **Durability and Reliability Tests**: Capacitors undergo mechanical stress tests to evaluate their durability under various conditions, including temperature fluctuations and mechanical vibrations.

2. **Environmental Testing**: Environmental tests assess the capacitor's performance under extreme conditions, such as humidity and temperature variations.

C. Compliance with Standards

1. **Industry Standards**: Capacitors must comply with various industry standards, such as ISO and IEC, to ensure safety and performance.

2. **Certification Processes**: Certification from recognized organizations provides assurance to manufacturers and consumers that the capacitors meet established quality and safety standards.

VI. Innovations and Future Trends

A. Advances in Materials Science

1. **Development of New Dielectric Materials**: Research is ongoing to develop new dielectric materials that offer higher capacitance and better thermal stability, which could lead to more efficient capacitors.

2. **Nanotechnology in Capacitor Production**: The integration of nanotechnology in capacitor manufacturing is paving the way for smaller, more efficient components with enhanced performance characteristics.

B. Automation and Smart Manufacturing

1. **Role of Robotics in Production**: Automation is increasingly being adopted in capacitor production, with robotics playing a key role in improving efficiency and precision.

2. **Industry 4.0 and IoT Integration**: The integration of IoT technologies in manufacturing processes allows for real-time monitoring and data analysis, leading to improved quality control and production efficiency.

C. Sustainability in Capacitor Manufacturing

1. **Eco-friendly Materials and Processes**: There is a growing emphasis on using sustainable materials and processes in capacitor manufacturing to reduce environmental impact.

2. **Recycling and Waste Management**: Efforts are being made to develop recycling processes for capacitors, ensuring that materials can be reused and waste is minimized.

VII. Conclusion

In summary, the production of parallel plate capacitors involves a complex interplay of materials, design considerations, and manufacturing processes. From substrate preparation to quality control, each step is crucial in ensuring the performance and reliability of these essential components. As technology continues to advance, innovations in materials science, automation, and sustainability will shape the future of capacitor manufacturing, paving the way for more efficient and environmentally friendly solutions in the electronics industry.

VIII. References

1. Academic Journals

2. Industry Reports

3. Standards Organizations Publications

This blog post provides a comprehensive overview of the common production processes for parallel plate capacitors, highlighting the importance of each stage in the manufacturing process and the ongoing innovations that will shape the future of this critical technology.